Overview

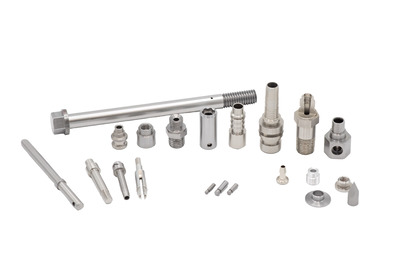

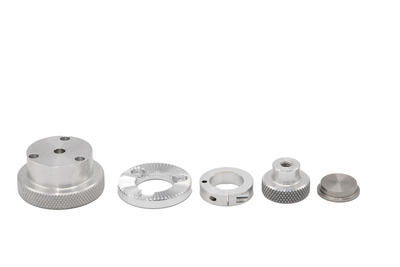

Our Swiss Machining services specialize in producing small, intricate parts with exceptional precision. Swiss machines are uniquely suited for components with tight tolerances and complex features, often required in medical devices, aerospace components, and precision instruments.

Applications

Ideal for medical implants, aerospace connectors, electronic components, and precision hardware.

Capabilities

- High Precision: Achieving tight tolerances.

- Small Diameter Components: Expertly machining parts with small diameters.

- Complex Features: Including threads, grooves, slots, and intricate profiles.

- Material Expertise: Proficient in machining stainless steel, steel, aluminum, brass, plastics, and more.

Benefits

- Exceptional Accuracy: Perfect for high-precision applications.

- Surface Finish Quality: Produces superior surface finishes, reducing the need for secondary operations.

- Efficient Production: Simultaneous multi-channel machining reduces production time.

- Bar feeding capability

Need ultra-precise components for your critical applications?

Overview

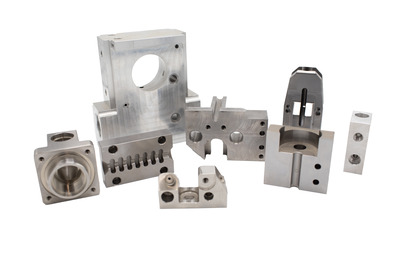

Our CNC Milling services involve movement along multiple axes to create you simple or complex part. CNC milling is versatile and can produce everything from simple flat surfaces to intricate 3d contours.

Applications

Ideal for aerospace components, medical devices, automotive parts, and custom machinery.

Capabilities

- Axis Movement: 3-axis and 4-axis milling capabilities.

- Workpiece Size: Handling parts up to 40 inches in length.

- Complex Geometry: Ability to machine pockets, slots, holes, and 3d surfaces.

- Material Diversity: Proficient in machining a wide range of materials.

- 3D milling capability

Benefits

- Design Flexibility: Capable of producing complex parts that are difficult to machine using other methods.

- Precision: Achieves tight tolerances and excellent surface finishes.

- Efficiency: High-speed machining reduces production times.

Ready to take your complex designs from concept to reality?

Overview

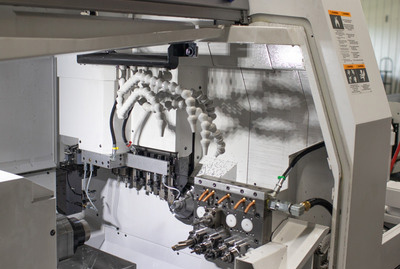

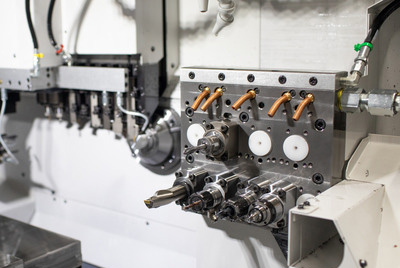

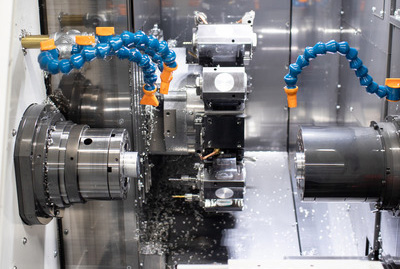

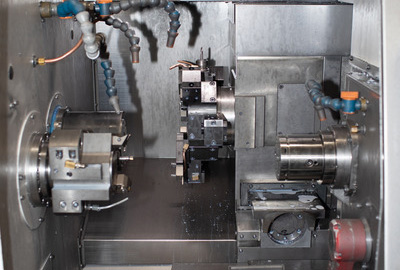

Our CNC Turning services involve movement along multiple axes to create your simple or complex part. Our machines include main and sub spindles that will allow for front and backside work, along with turret milling and Y-axis. CNC milling is versatile and can produce everything from simple flat surfaces to intricate 3d contours.

Applications

Ideal for automotive components, hydraulic shafts, aerospace parts, and industrial machinery.

Capabilities

- Diameter Range: Capable of handling parts up to 8 inches in diameter.

- Length Capacity: Machining components up to 20 inches in length.

- Complex Contours: Ability to produce tapers, threads, grooves, and complex profiles.

- Material Range: Expertise in working with stainless steel, steel, aluminum, plastics, and composite materials.

Benefits

- High Efficiency: Quick setup and automated processes reduce lead times.

- Precision and Repeatability: Ensures consistent quality across production runs.

- Versatility: Suitable for both simple and complex geometries.

- Bar feeding capability